SFI WATERFALL – Raising the Standard in Gentle Salmon Delousing

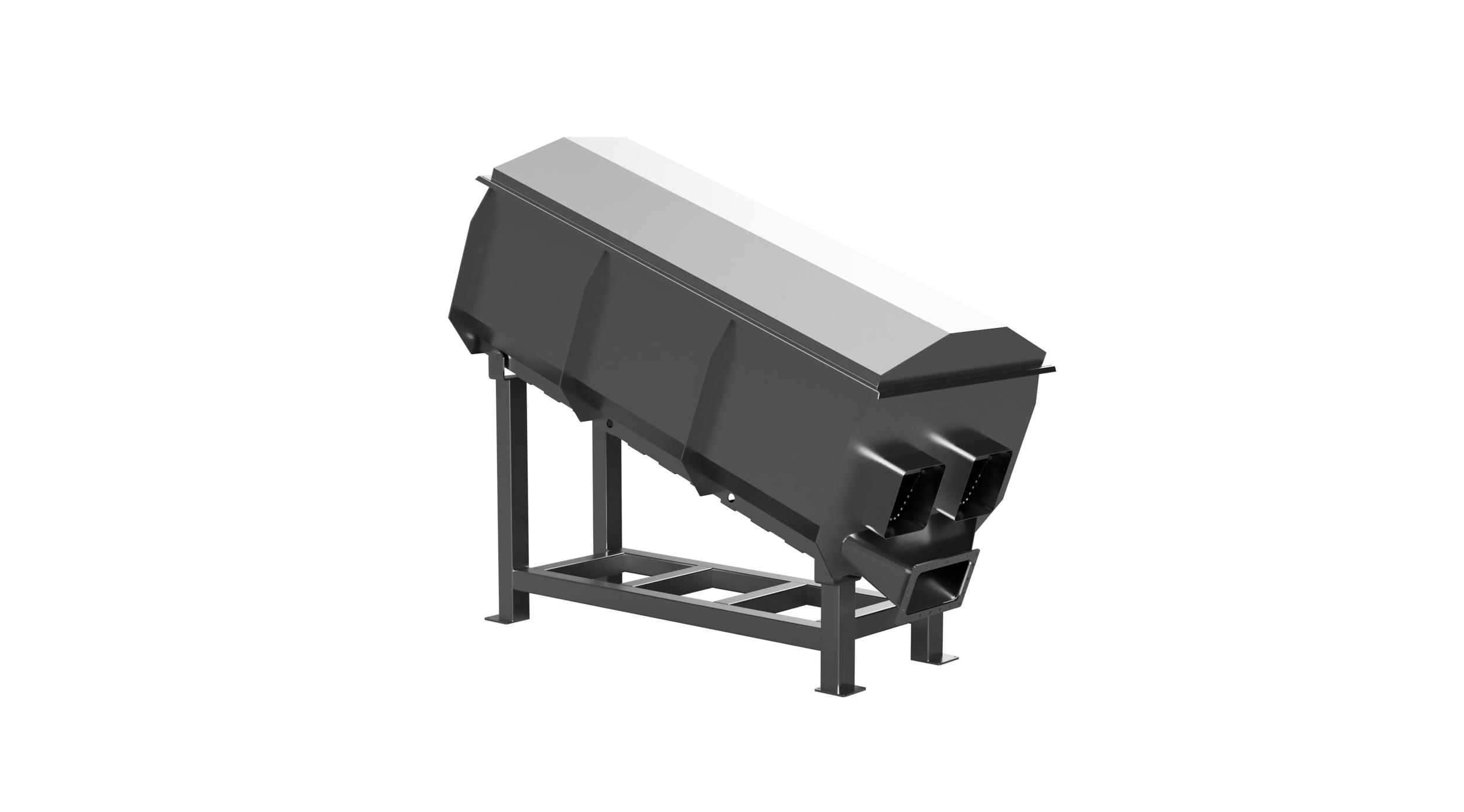

Illustration of SFI WATERFALL for processing plants with 2 lines, 3 flushers per line – capacity 5,000+ fish per hour.

Sea lice remain one of aquaculture’s toughest challenges. For years, producers have balanced fish welfare, efficiency, and export demands — knowing that mistakes can be costly. Several well-known cases show how shipments have been stopped at Chinese border inspections, where zero-tolerance rules leave no room for error. For exporters, reducing that risk is just as important as effective lice removal.

The SFI SYSTEM has already proven itself as one of the gentlest and most efficient mechanical delousing solutions in the industry. With installations running successfully, it has built a reputation for reliable performance and fish welfare.

From this foundation, SFI has now developed the next step: SFI WATERFALL. Built on two patents and years of operational feedback, it introduces a new sloped geometry combined with dual water-handling. This means cleaner separation between fish and process water, reduced risk of contamination, and better control for processors.

Designed for processing plants, wellboats, and service vessels, SFI WATERFALL is more than a delousing unit. It is a safeguard for producers who need to meet strict market requirements, especially in China. By combining gentle fish handling with hygienic water separation, it reduces the risk of non-compliance and gives exporters greater confidence.

SFI WATERFALL is the result of listening to farmers, learning from challenges, and pushing technology forward. It is a tool built for the future of salmon processing — where fish welfare, sustainability, and market access all depend on getting the details right.

Read more here: SFI WATERFALL